Products

Flow

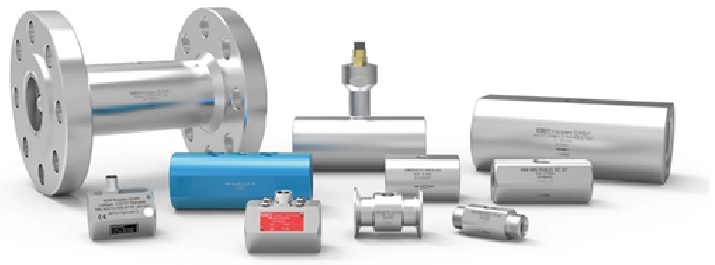

KEM

With more than 50 years of experience in the flow measurement field and numerous innovative and customer-specific product developments, we are your qualified and competent contact for flow measuring technology and calibration. We solve even the most challenging measurement problems in close cooperation with you. Our unique solutions are proven worldwide for manufacturing exotic material flow meter and handling high flow-low pressure application in offshore chemical injection skids. KEM offers a broad selection of measuring principles for this purpose. We develop, produce, and deliver high quality Gear Flow Meters, Turbine Flow Meters, Helical Flow Meters and Micro Flow Meters as well as Coriolis Mass Flow Meters worldwide. Specific accessories complement the product range. We also specialized in special or exotic material flow meter.

Coriolis Mass Flow Meter

Turbine Flow Meter

Helical Flow Meter

Coriolis Flow Meter

Micro Flow Meter

Kings

King's Energy Services started in 1977 with one truck, one prover and one aspiring entrepreneur named Gary King. Over 40 years later King's Energy Services has grown to over 80+ staff and multiple locations. King's Energy is now a recognized supplier of quality instrumentation and valve products and services throughout Canada.

King's Energy Services also has Optical Flow Meter

Focus® 2.0 Optical Gas Flow Meter

McCrometer

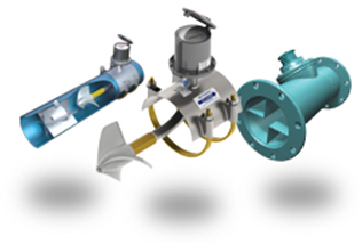

McCrometer is a leading global flow instrumentation specialist. We specialize in the design, manufacture, installation and testing of flow metering solutions. Instrument, process, facility and consulting engineers worldwide have confidently chosen McCrometer’s flow meters for more than 60 years.

McCrometer's V-Cone® and Wafer-Cone® Flow Meters have proven themselves equal to the challenges of the oil and gas industry for three decades. They offer unique performance and low cost of ownership advantages. The result is a dramatic savings in layout space, piping and weight that greatly reduces installation complexity and cost. Less is truly more with the McCrometer V-Cone Flow Meter.

Differential Pressure Flow Meter

Built-In flow condition design ideal for use in tight-fit and retrofit installations.

McCrometer's V-Cone® Flow Meter is an advanced differential pressure instrument, which is ideal for use with liquid, steam or gas media in rugged conditions where accuracy, low maintenance and cost are important. The V-Cone is especially useful in tight-fit and retrofit installations.

V-Cone Flow Meter

VM V-Cone

Wafer Cone

FS100 Flow Straightener

Flow Connect

Smart Output

SPI MAG

Exact™ Steam

FPI MAG

Electromagnetic Flow Meters

Water Specialties

Calibration Software

Mc Mag3000

McCrometer CONNECT

Ultra Mag

Dura Mag

Propeller Flow Meters

McPropeller

SAGE

Sage Metering is manufacture MASS FLOW METERS Increase process efficiency. Conserve energy. Improve the environment.

SAGE 200™ FLOW METERS

SAGE PARAMOUNT INDUSTRIAL MASS FLOW METER